Imveliso elungileyo ayicutshungulwa kuphela, kodwa ikwafuna unyango olwahlukileyo lomphezulu ukufikelela ukuxhathisa ukubola, ukuxhathisa ukunxiba, ubuhle, kunye nokwandisa ubomi benkonzo.I-RCT MFG ineminyaka emininzi yamava kwi-CNC processing kunye nokusetyenzwa kwenaliti yokubumba, ikwabonelela ngothotho lweenkonzo ukusuka ekuqhubeni ukuya kunyango olungaphezulu ukuya kwindibano.Ke ngoko, ukongeza kwitekhnoloji yokwenziwa, ikwanamava atyebileyo kunyango lomphezulu.Inkqubo ekhoyo yonyango yomphezulu ibandakanya: ukupeyinta, ipeyinti yokubhaka, ukutyabeka ngomgubo, ukuqhushumba kwesanti, ukuqhushumba kwembumbulu, i-anodizing, ifilimu eshinyeneyo ye-anodizing, i-micro-arc anodizing, i-electroplating, i-electrophoresis, i-laser engraving, i-silika yoshicilelo lwesikrini, intsimbi ehlanjululweyo, ukugulisa isibuko, ukudaya, umnyama, ipateni yeCD, i-etching, iglosi ephezulu, ipateni ye-etch, i-Epoxy, njl., nceda ukwenza iimveliso zakho zibe kumgangatho ophezulu.

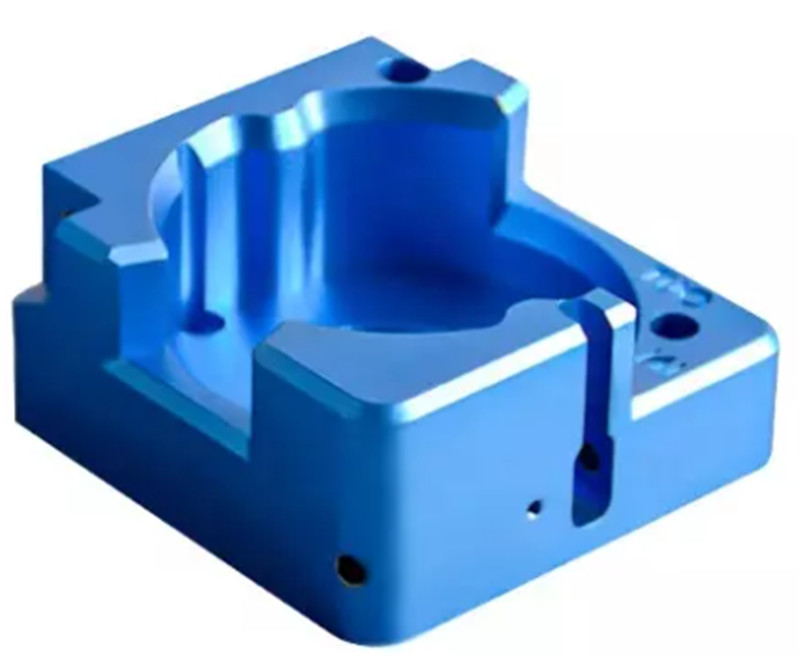

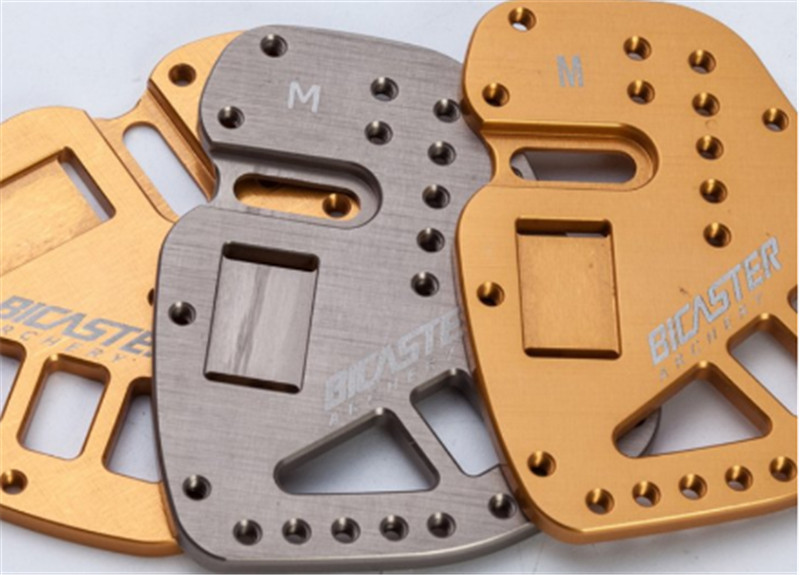

Anodizing

Yinkqubo ye-electrolytic oxidation, eguqula umphezulu wezinto kwifilimu ekhuselayo, eyenza kube nzima ukukhupha i-oxidize kunye ne-corrode, ukwandisa ubomi kunye nokufezekisa ukubonakala kwemibala eyahlukeneyo.Unyango lwe-anodizing olusetyenziswa ngokuqhelekileyo lwahlulahlulwe: i-anodizing eqhelekileyo, i-anodizing yensimbi exutywe, i-anodizing enzima, i-anodizing yefilimu eninzi, i-micro-arc oxidation, njl.

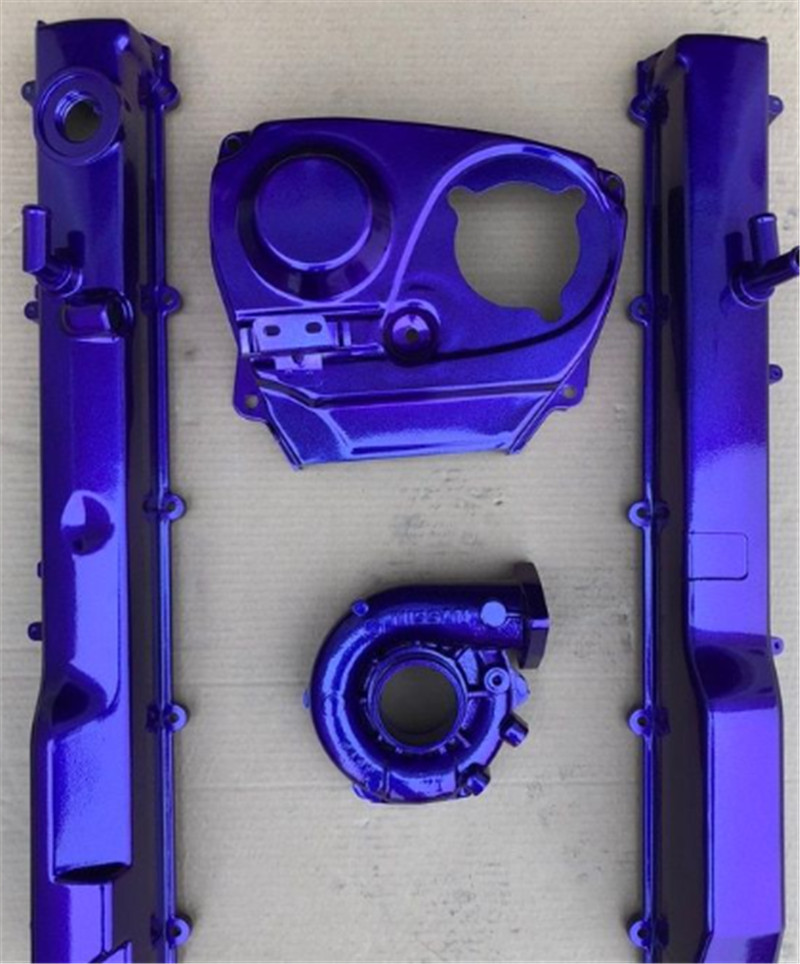

Electroplating

Inkqubo esisiseko ye-electroplating kukuntywilisela inxalenye kwisisombululo setyuwa yesinyithi njenge-cathode, kunye nepleyiti yensimbi njenge-anode, kwaye idlulise i-current ukuze ifake i-coating efunwayo kwindawo.Isiphumo esifanelekileyo se-electroplating siya kwenza imveliso yakho ibe yifashoni ephezulu kunye nayo.Kwimarike engcono, umgangatho we-electroplating uquka ukufakwa kwe-copper, i-nickel plating, i-silver plating, i-golden plating, i-chrome plating, i-galvanizing, i-tin plating, i-vacuum plating, njl.

Ukugquma kwe-Electrophoretic

Ngophuculo oluqhubekayo lwemfuno yemizi-mveliso, itekhnoloji yokwambathisa ye-Electrophoretic inokwenza ngokwezifiso imibala eyahlukeneyo, igcine i-metallic luster kwaye iphucule ukuxhathisa kokubola komphezulu, onempembelelo encinci ekuchanekeni kwemveliso.Ubukhulu bumalunga ne-10-25um, kwaye ezityebileyo nazo zinokulungiswa

Ukunyamezela

I-Passivation, eyaziwa nangokuthi unyango lwe-chromate, yinkqubo yokukhetha esusa igrisi engaphezulu, i-rust, kunye ne-oxides ngokuntywiliselwa okanye ukucocwa kwe-ultrasonic.Ngokusebenzisa imichiza yesisombululo se-passivation, inokuthintela ukubola kunye nokwandisa ixesha elide.Umbala wefilimu ye-passivation uya kutshintsha ngezinto ezahlukeneyo.I-Passivation ayiyi kwandisa ubukhulu bemveliso, kwaye akukho mfuneko yokukhathazeka malunga nokuchaphazela ukuchaneka kwemveliso.

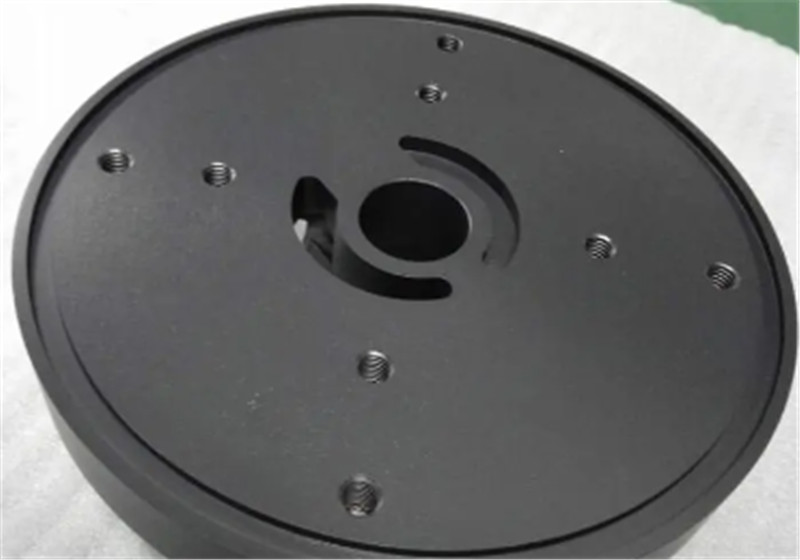

Yenziwe mnyama

Ubumnyama bukwabizwa ngokuba yi-bluing.Umgaqo-siseko kukuntywilisela imveliso kwisisombululo esinamandla sekhemikhali ye-oxidizing ukwenza ifilimu ye-oxide kwindawo yesinyithi ukuhlukanisa umoya kunye nokufezekisa injongo yokuthintela umhlwa.Le nkqubo iyasebenza kwizinto zetsimbi.

QPQ (Cima-isiPolish-Cima)

Kubhekiselele ekubekeni iinxalenye zentsimbi ezinentsimbi kwiindidi ezimbini zeebhafu zetyuwa ezineempawu ezahlukeneyo, kunye nokungena kwizinto ezahlukeneyo kumphezulu wesinyithi ukwenza umaleko wokungenwa odibeneyo, ukuze kuphunyezwe injongo yokuguqula umphezulu wamalungu.Inokumelana nokunxiba kakuhle, ukumelana nokudinwa, ukuxhathisa ukubola kunye nokuguqulwa okuncinci.Le nkqubo isebenza kuzo zonke izinto zetsimbi.

(Qaphela: Iimveliso zensimbi ezingenasici azinakwenziwa mnyama, kwaye umphezulu unokuba mnyama kuphela yi-QPQ)

Ukukrolwa kweLaser

Umkrolo weLaser, okwabizwa ngokuba yilaser marking, yinkqubo yonyango engaphezulu kusetyenziswa imigaqo yokubona ukwenza i-LOGO okanye iipateni kwiimveliso.Isiphumo sokukrolwa kwelaser sisisigxina, umgangatho womphezulu uphezulu, kwaye ufanelekile kwiimveliso ezenziwe ngezinto ezahlukeneyo zetsimbi kunye neplastiki.

Ukuprintwa kwesikrini sesilika

Ukuprintwa kwesikrini sesilika kuthetha ukuba i-inki idlulisela ipateni kwimveliso ngesikrini.Umbala we-inki unokwenziwa ngokweemfuno zabathengi.I-RCT MFG yenze imibala emi-6 kwimveliso efanayo, kuquka emnyama, ebomvu, eluhlaza okwesibhakabhaka, etyheli namhlophe.,luhlaza.Ukuba ufuna isiphumo soshicilelo lwesikrini sesilika lube lomelele ngakumbi, unokongeza umaleko we-UV emva kokuprintwa kwesikrini sesilika ukwandisa ubomi bayo.Ukuprintwa kwesikrini sesilika kufanelekile kwiintsimbi ezahlukeneyo kunye nezixhobo zeplastiki, kwaye zinokudityaniswa nonyango olungaphezulu olunje nge-oxidation, ukupeyinta, ukutshiza ngomgubo, i-electroplating, kunye ne-electrophoresis.

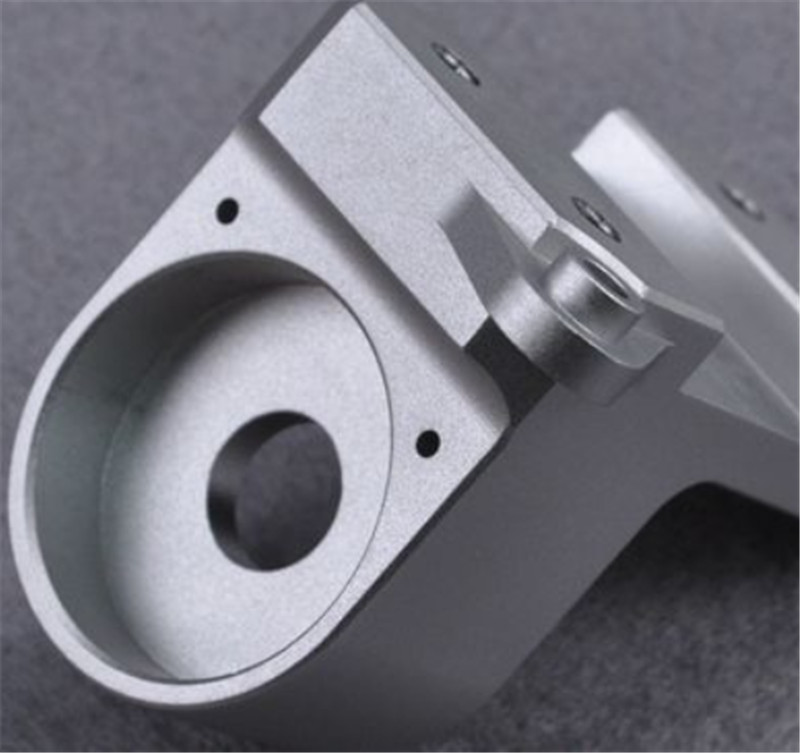

Ukugudisa

Ukupholisha kukwenza imveliso ibe ntle, iguquguquke kwaye ikhusele umphezulu.Ukucwenga kunye nokungafihli lukhetho olulungileyo kuwe.Ukupholishwa kweemveliso zehardware kwahlulwe kwaba ukupolisha ngesandla, ukupolisha ngoomatshini, kunye nokupholishwa kwe-electrolytic.I-Electrolytic polishing ingasetyenziselwa ukutshintsha i-polish enzima yomatshini, ngakumbi kwiindawo ezinemilo enzima kunye neendawo ekunzima ukuzisebenzisa ngokupolisha ngesandla kunye neendlela zoomatshini.I-Electrolytic polishing isoloko isetyenziselwa intsimbi, i-aluminium, ubhedu kunye nezinye iindawo.

Isinyithi esixutywe

Isinyithi esixutyweyo yindlela yonyango yomphezulu eyenza imigca phezu kwendawo yokusebenza ngebhanti e-flat-pressed abrasive kunye ne-brush ye-roller engalukiweyo ukufezekisa umphumo wokuhlobisa.Ukunyangwa kwebrashi yomphezulu kunokubonakalisa ukuthungwa kwezinto zetsimbi, kwaye kuya kuthandwa ngakumbi kubomi banamhlanje.Isetyenziswa kakhulu kwiifowuni eziphathwayo, iikhompyuter, iimonitha, ifenitshala, izixhobo zombane kunye namanye amaqokobhe.

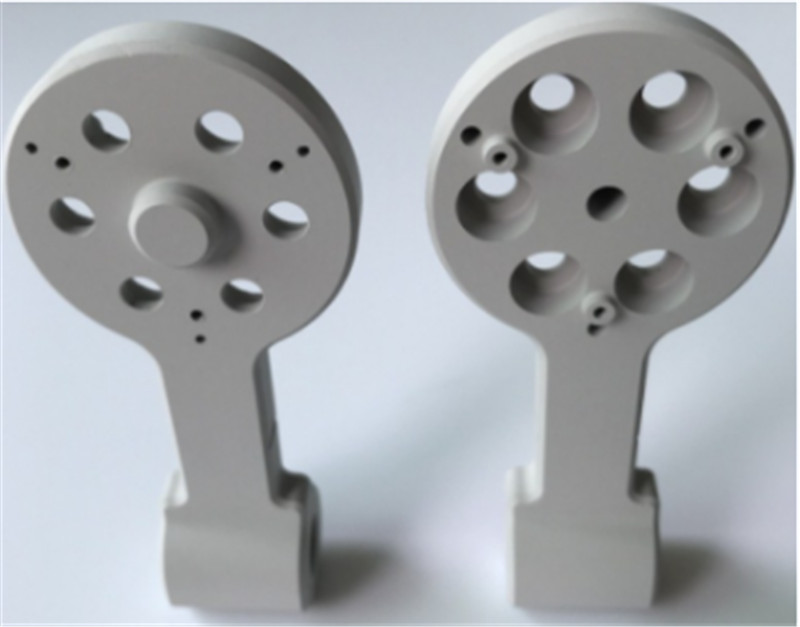

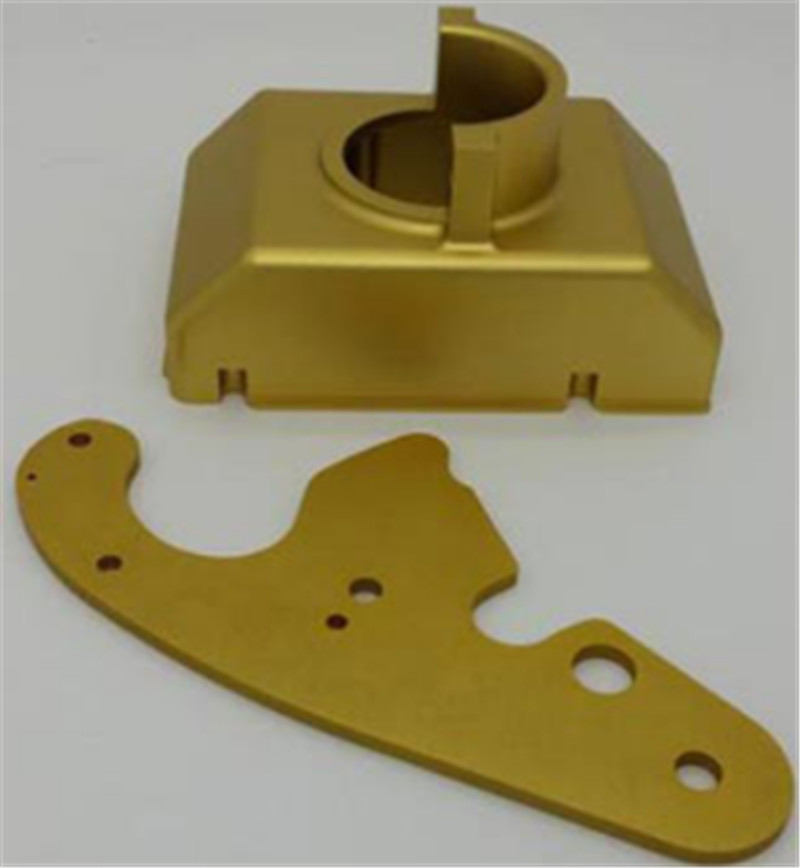

Ukutshiza ngepeyinti kunye nokutshiza ngomgubo

Ukutshiza ngepeyinti kunye nomgubo wokutshiza zimbini zonyango oluqhelekileyo lomphezulu kwiindawo zehardware zokutshiza, kwaye lolona nyango luxhaphakileyo lusetyenziswa kwindawo echanekileyo kunye nokwenza ibhetshi encinci.Bangakwazi ukukhusela umphezulu kwi-corrosion, i-rust, kwaye banokufezekisa umphumo wobuhle.Zomibini zokutshiza umgubo kunye nepeyinti zinokwenziwa ngokwezifiso ngeendlela ezahlukeneyo (imigca emihle, imigca erhabaxa, imigca yesikhumba, njl.njl.), imibala eyahlukeneyo, kunye namanqanaba ahlukeneyo eglosi (i-matte, flat, high-gloss).

Ukuqhunyiswa kwesanti

ISandblasting yenye yonyango oluqhele ukusetyenziswa kumphezulu kwiimveliso zehardware.Inokuphucula ukucoceka kunye noburhabaxa, kunye nokwandisa ukunamathela kunye nokuqina phakathi kwemveliso kunye nokwaleka.Ke ngoko, unyango oluninzi lwangaphezulu lukhetha ukuqhunyiswa kwesanti njengonyango lwangaphambili.Ezinje: ukuqhunyiswa kwesanti + i-oxidation, i-sandblasting + i-electroplating, i-sandblasting + i-electrophoresis, i-sandblasting + uthuli, i-sandblasting + ipeyinti, i-sandblasting + passivation, njl.

Ukutshiza ngeTeflon

Ikwabizwa ngokuba yi-Teflon yokutshiza, lunyango olukhethekileyo lwangaphezulu.Ineempawu eziphezulu ze-anti viscosity, i-nonviscosity, ukumelana nobushushu obuphezulu, ukukhuhlana okuphantsi, ubunzima obuphezulu, ukungabi manzi, kunye nokuxhathisa imichiza ephezulu.Ke ngoko, isetyenziswa kakhulu kwishishini lokutya, i-tableware, ikhitshi, ishishini lamaphepha, izixhobo zonyango, iimveliso zombane kunye neemveliso zemoto, izixhobo zeekhemikhali, njl., kwaye inokukhusela izixhobo kwi-corrosion yeekhemikhali ukwandisa ubomi benkonzo yeemveliso.

Etching

I-Etching yindlela yokususa izinto usebenzisa iikhemikhali okanye impembelelo yomzimba.Ngokuqhelekileyo ibhekisa kwi-etching, ekwabizwa ngokuba yi-photochemical etching, ebhekisa ekususeni ifilimu ekhuselayo yendawo eza kufakwa emva kokwenziwa kwepleyiti yokuvezwa kunye nophuhliso, kunye nokunxibelelana nesisombululo sekhemikhali ngexesha lokudibanisa ukufezekisa isiphumo sokuchithwa kunye nokubola, ukwenza isiphumo i-concave-convex okanye ukubumba umngxuma.

IMD

Kwi-Mold Decoration (IMD) yindlela eneendleko zokuhombisa iinxalenye zeplastiki.Iqulathe amanyathelo amane: Ukuprinta, Ukubumba, Ukucheba kunye ne-Injection Molding.Kwaye Bubuchwephesha bokuhombisa umphezulu obuthandwayo kumazwe ngamazwe.Umphezulu wenziwe lukhuni kunye nefilimu ecacileyo, umaleko wepatheni yoshicilelo oluphakathi, umaleko wokubumba wangemuva, kunye nombindi we-inki unokwenza imveliso imelane nengxabano., thintela umphezulu ukuba ungakrwelekanga, kwaye unokugcina umbala oqaqambileyo kwaye ungabi lula ukucima ixesha elide.

Ushicilelo lwePad

Ushicilelo lwePad, olukwabizwa ngokuba yitampografi okanye ushicilelo lwetampo, yinkqubo yoshicilelo ye-offset engathanga ngqo (igravure) apho isilicon pad ithatha umfanekiso we-2-D kwi-laser ekrolwe (etched) yokushicilela ipleyiti (ekwabizwa ngokuba yi-cliché) kwaye iyigqithisele kwi-3- D into.Ngombulelo kwi-pad printing, ngoku kunokwenzeka ukuba uprinte zonke iintlobo zeemveliso ezinzima ezifana ne-curved (convex), i-hollow (concave), i-cylindrical, i-spherical, i-engile edibeneyo, i-textures, njl.

Ukuprintwa kokuhambisa amanzi

Ukuprintwa kokuhanjiswa kwamanzi luhlobo lokushicilela olusebenzisa uxinzelelo lwamanzi kwi-hydrolyze iphepha lokudlulisa / ifilimu yeplastiki kunye neepatheni zombala.Inkqubo yezobuchwepheshe ibandakanya ukuveliswa kwephepha lokuprinta lokudluliswa kwamanzi, ukumanzisa iphepha leentyatyambo, ukuhanjiswa kwepateni, ukomisa, kunye nemveliso egqityiweyo.

Ukwaleka okuqhubayo

I-conductive coating luhlobo lwepeyinti engasetyenziselwa ukutshiza.Inokuqhuba umbane emva kokoma ukwenza ifilim yepeyinti, ukuze ikhusele ukuphazamiseka kombane.Okwangoku, isetyenziswa kwimimandla emininzi yasemkhosini neyasekuhlaleni efana ne-elektroniki, izixhobo zombane, inqwelomoya, ishishini lemichiza, ushicilelo, njl.

Ixesha lokuposa: Apr-11-2023